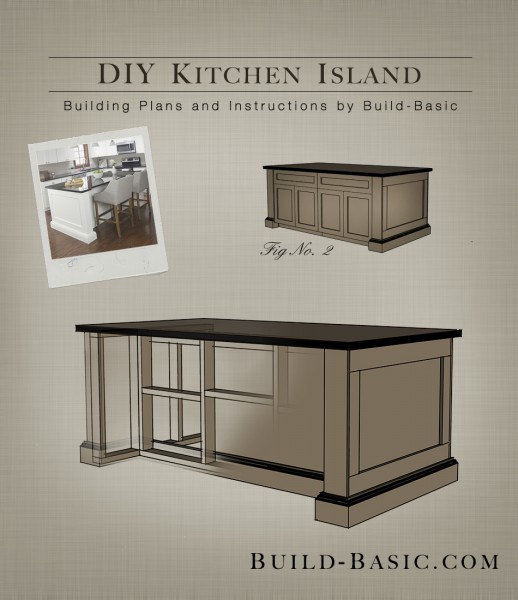

This kitchen island is made from a surprisingly simple frame built around two stock cabinets, and can be sized to fit ANY base cabinets by changing only ONE measurement. When we started our kitchen remodel, this exact island was quoted to cost just over $4,000 (not including the countertop…yikes!). We built it for under $250 using only basic tools (i.e. drill, miter saw, circular saw, etc). Building anything this large may seem daunting, but all the cuts are fairly simple. Believe it or not, the hardest part is mitering the baseboard.

For reference, my frame is built to house two 36-inch-wide by 34½-inch-tall base cabinets, for an overall size of 83¼” x 43″. If you have cabinets of a different width than mine, you’ll only need to adjust the width of the frame by changing one measurement on my cut list—the sides will be built the same. I opted for a 1½ countertop overhang (with a rounded inset detail on the seating side) for a total countertop size of 86¼” x 46″. Please note, I don’t recommend ordering a countertop before the build, as variations in cabinet size and stock lumber can adjust your final dimensions. Instead, I suggest building this frame with the cabinets on hand to double check their fit, and then templating for the countertop once the build is complete.

Cost: $240 (plus base cabinets and countertop)

Time: 2 Work Days (plus paint time)

Difficulty: Moderate. The cuts are fairly easy, but ensuring the assembly remains level and square takes finesse.

Click HERE to purchase these plans and get the full materials list, cut list, measurements, drawings, board planning sheet and more!

Click

HERE to purchase these plans and get the full materials list, cut list, measurements, drawings, board planning sheet and more!

Steps

1. Cut the Framing Boards

This island is built to house two 36-inch base cabinets, but can easily be modified by simply adjusting the width of the center wall. Using the

Board Planning Sheet, cut the 2×4 boards to create the structural framing for the center and side walls. To ensure the lengths of “like parts” are equal, use the first cut of each group to mark each subsequent cut. For example, I used the first 31½ inch 2×4 stud to mark the cut length of each remaining stud. When complete, set all the studs side-by-side to ensure they are cut to the exact same length. One tall stud could prevent the finished island from sitting level.

2. Mark the Stud Locations

2. Mark the Stud Locations

To ensure the studs sit plumb (perfectly vertical) between the horizontal top and bottom 2x4s of each wall’s framing, lay the top and bottom 2x4s together and mark a line at the location of each stud. For example, on the side walls, the doubled-up studs shown in the illustration below will sit 12¼ inches from the front edge–or the “seating side”–of each wall. Lining the studs up with these marks will help keep the assembly square.

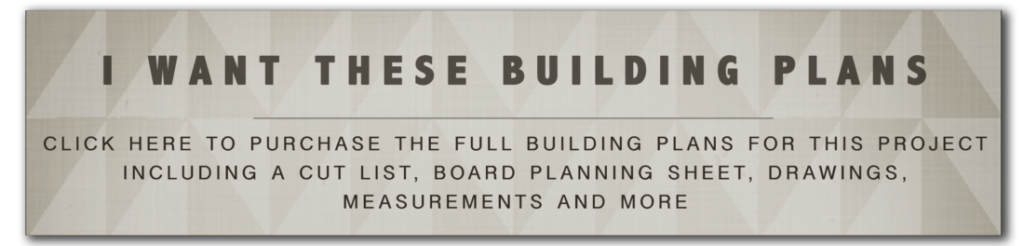

3. Layout the Side Wall Framing

3. Layout the Side Wall Framing

On a flat surface, lay the parts of one side wall in place. Position the studs between the top and bottom 2x4s. The two outer studs should sit flush with the ends of the top and bottom 2x4s while the doubled-up stud should be positioned using the line marked in step 2.

4. Assemble the Side Wall Framing

Apply glue to the ends of each stud, lay them back in place, and drive two 2½-inch wood screws through the horizontal 2x4s and into the ends of each vertical stud. Repeat to assemble the second wall.

5. Attach the Side Wall Panel

Using the Board Planning Sheet below, cut a piece of plywood to the total height and width of the side wall. Apply a bead of wood glue to the outer edges of the 2×4 framing. Lay the plywood in place and secure it using 1-inch wood screws. Position the screws around the perimeter of each panel to ensure the stiles and rails will cover them. Repeat this step to cut and attach the second side wall’s panel.

TIP: Get straighter cuts with a circular saw using our simple DIY Cutting Fence Tutorial.

6. Layout the Center Wall Framing

Using the same method described in step 2, mark the center wall’s stud locations on the top and bottom 2x4s. Position the studs between the top and bottom 2x4s on a flat work surface. Using a drill/driver and 2½-inch wood screws, secure each stud in place by sinking two screws through the horizontal 2x4s and into each end of the studs.

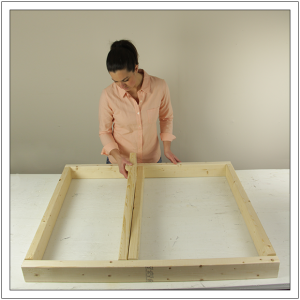

7. Install the Crosspieces

Secure a crosspiece in each gap between the studs using 2½-inch wood screws This will help hold the wall square and sturdy. Offset the center crosspieces so the drill/driver can sink through the ends of the board.

8. Attach the 2×4 Padding and Panel

To create a larger nailer for installing the cabinets, place two 2×4 boards on edge against the back for the center wall, flush with its top and bottom edges. The drawing below shows the center wall from the backside so you can more clearly see the 2×4 padding placement. Cut the center wall’s panel to size and fasten it to the opposite side of the wall using 1-inch finish nails.

9. Cut the 1x Pieces

Cut the vertical 1×6 end caps to the height of the walls. Cut the horizontal 1×5 rails and filler boards to the width of the side wall. Wait to cut the vertical stiles until the rails are installed and you can more accurately measure the distance between them.

10. Attach the Filler Boards

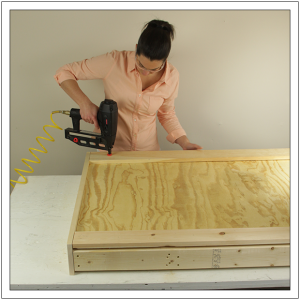

Position a filler board on the panel along the bottom edge of each side wall. Using a nail gun and 1 inch finish nails, attach the board.

11. Install the End Caps

Position the 1×6 end caps on the front and back edge of each side wall flush with face of the filler board. I used another scrap 1x near the top of the walls to help position each 1×6. Nail the boards in place with 1 inch nails using a nail gun. Since these nail holes will need to be filled, ensure the nails sink below the surface of the wood.

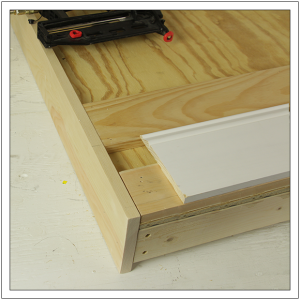

12. Add the Top Rail

Slide the top rail between the end caps and position it flush with the top edge of the side wall. Nail it in place. Repeat on the second side wall.

13. Position and Install the Bottom Rail

Mark the height of the baseboard on the edges of the end caps. Position the lower rail ¼ inch below the height of the baseboard so that the baseboard will slightly overlap the rail, but not so much so that it looks noticeably thinner than the top rail. Nail the rail in place and repeat on the other side wall.

14. Size and Insert the Stiles

Measure the distance between the rails, and cut the stiles to size. Don’t be afraid to cut each stile slight longer than your measurement, and then make several cuts until the board fits tightly between the rails. Secure each stile in place tight between the rails and pressed against the edge of the adjacent end cap.

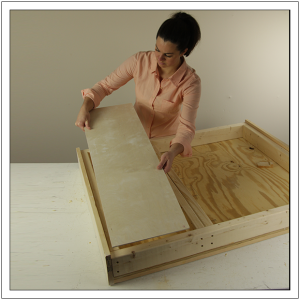

15. Attach the Inside Panel

Using the Board Planning Sheet, cut the inside plywood panels to size. Flip the assembled walls on their face. Be careful not to dent the stiles and rails. Position the panels against the edge of the “stool side” end caps, as shown. Secure the panels by nailing through the plywood and into the edges of the 2×4 framing.

16. Place the Cabinet Filler Board

Cut the cabinet filler board to the height of the wall and place it along the edge of the “cabinet side” end caps. Secure it in place. Repeat on the other side wall.

17. Sand and Smooth the Assembly

Using a block plane trim the edges of the end caps until they sit perfectly flush with the faces of the stiles and rails and the inside panels. Fill all visible nail holes with wood filler. Sand all the parts, especially where two boards butt against each other. The smoother the joints feel, the more likely it is to look like one solid piece once it’s painted. I find this step to be the most crucial for a professional-looking final project.

18. Secure the Baseboard Padding – Stool Side

To further pad the thickness of the island’s footprint, I used an additional board behind the baseboard. This is, of course, optional. To do so, cut 1x material to the width of side walls. We chose to miter the corners since their top edge would be visible. On the stool side, cut a piece to the width of end cap leaving a 45-degree miter on both ends. Wait to cut the piece for the inside panels until the walls are assembled.

19. Secure the Baseboard Padding – Cabinet Side

On the cabinet side, cut the 1x padding with a mitered end–to meet the miter of the pieces along the face of the side wall–and a square cut end to finish where the end cap will meet the cabinet.

20. Dryfit the Base Cabinets

Set the center and side walls upright. Either set the cabinets in place, and then position the walls around them, or stand the walls in place, and then slide the cabinets into the opening. Using a framing square, ensure that the side walls are square to the center wall, and they fit tight to the cabinets. Slide a 4 foot level over the top edges of the walls to ensure everything is level and there are no high spots.

21. Paint the Parts

To mimic the look of the surrounding cabinets, I had the paint store color-match a cabinet door. I prepped with a thick, high-adhesion primer and finished with three coats of an enamel paint, which typically has an extra-tough finish. Sand between every coat to smooth brush strokes and drips, and create a long-lasting, professional-looking finish. In addition, prime and paint the baseboard and the additional 1x that will be used to pad out the baseboard along the center wall and inside panels.

22. Level the Center and Side Walls

Once the paint is dry, set all the parts back in place and use a measuring tape, framing square, and 4-foot level to adjust each piece until it sits level, plumb, and square to the remaining parts. Measure between the front end cap of each wall, and then the back end cap of each side wall to ensure the measurements are equal and the walls aren’t twisted. Use shims to make minor adjustments.

23. Assemble the Center and Side Walls

Clamp the parts in place, remove the cabinets, and screw through the center wall’s framing and into the side wall studs on each side. Because we were also redoing our flooring, I screwed through the framing of all three walls and into the floor, but this is not required.

24. Install the Base Cabinets and Toekick

Slide the cabinets into the opening. Level the cabinets to the island walls and each other. Screw through the back wall of the cabinets and into the 2×4 padding. Insert spacer blocks if necessary and screw the cabinets together and to the side walls. Using a nail gun and 1 inch finish nails, secure the cabinets’ toekick against the back of the recessed foot of each cabinet.

25. Caulk the Joints

Using a caulk gun, caulk the joints where the side wall panels meet the center wall panel. Either use white caulk like I did, or clear if your island is painted a color.

26. Attach the Remaining Baseboard Padding

Size the remaining baseboard padding pieces that will fit along the inside panel on each side wall and the center wall. Miter their ends and dryfit them into place. Using a nail gun, attach the remaining baseboard padding using 1 inch finish nail. If possible, nail below the height of the baseboard to avoid visible nail holes once the baseboard is installed.

27. Cut and Install Baseboard

Cut and dryfit the baseboard in the same way as the baseboard padding pieces, mitering their edges.

28. Cut and Install the Baseboard – Side Walls

Secure the baseboard using a nail gun and 1 inch finish nails.

29. Cut and Install the Baseboard – Cabinet Side

Miter both ends of the baseboard pieces that fit along the end caps on the cabinet side of the island.

30. Cut and Install the Baseboard

Miter a piece of baseboard to finish the corner and then slide under the recessed toekick. Depending of the overlay of your cabinets, use a handsaw to notch the top edge of the baseboard so that the cabinet can open without obstruction. Fill the nail holes and joints, and then lightly sand and touchup the baseboard with paint where needed.

MORE BUILDING PLANS

2. Mark the Stud Locations

2. Mark the Stud Locations

3. Layout the Side Wall Framing

3. Layout the Side Wall Framing

Pingback: Kitchen Island | diyroomdecor101.net - DIY Room Decor

Brett Hayes

I am looking to start this project. I understand the last step about notching the baseboard to fit under the toe kick. But I cannot visualize the cabinet facing side. Could you provide a picture of the cabinet side of the finished product? Thank you!

James McClure

I was wondering about the baseboard padding……what was the height on it? Is the padding above the baseboard on final assembly? And if so how much above the baseboard is it? Thanks

Fred

What are the overall dimensions of your island and what size base cabinets were used?

Tom

Jenn….it appears the wood is basic pine and spruce or aspen plywood. Would you/ could you do this project with MDF? Much cheaper than other materials but I am wondering about painting MDF, especially edges. Thoughts?

Kara

We are going to start this. Thank you so much for this blog!