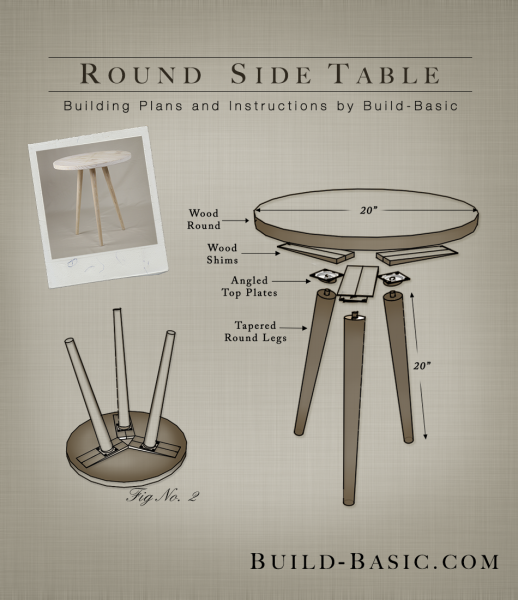

With a few tweaks to some stock parts, this simple table assembles easily yet pulls off the look of a custom-made, modern side table. Modifying the outdated bullnose edge and removing the metal foot from the tapered legs transforms this project into a high-end lookalike. Want to get your feet wet with the easy version? Just skip the customizations in steps 3-5 and 9.

Cost: $35

Time: 2 Hours

Difficulty: Easy. Just attach the legs to the stock wood round and customize however you like.

Paint stick and pencil

Drill/Driver

Framing Square

Jigsaw

Handsaw

Sanding block

(1) 23 ½ inch Wood Round @ 20 inch diameter

Steps

1. Mark the Tabletop’s Diameter

Lay a framing square (Lowes, $7) on the underside of the wood round. Position the corner of the square on the edge of the round and adjust the legs of the square so that they meet the edge of the round at equal distances. Mark the edge of the round at each leg. Remove the square and draw a line between the two points. This is the diameter of the round. Technically, the center of this line is the center of the wood round, but I prefer to repeat this process and create a second intersecting line for additional accuracy.

2. Find the Tabletop’s Center Point

Place the square back on the round and position the corner about a quarter turn from the diameter line. Following the instructions in the last step, mark the locations where the legs of the square meet the edge of the round. Draw a line between these points. The intersection of the two diameter lines creates a more accurate center point. To triple check, each line should be perfectly bisected (cut in half) by the other.

3. Create a Tool to Draw a Circle

If you’d like to cut the bullnose edge off the wood round like I did, you’ll need to first mark a circular cut line. To do so, we’ll skip the compass and make our own “circle-drawing” tool. Drill an 1/8-inch hole in one end of a paint stick, centered on the width of the stick. Measuring from the hole, mark the desired table radius on the paint stick. Mine was 10 inches, so the total diameter of my new table would be 20 inches. Drill a second small hole centered on the paint stick at the radius distance.

4. Mark the Cut Line

Place a pushpin or nail through the small hole in the end of the paint stick and position it on the center point of the wood round. Place the tip of a pencil in the second hole. Holding the pencil upright, spin the paint stick to create a circular mark on the wood round.

5. Cut the Wood Round

Using a jigsaw, cut in from the edge of the wood round to the line marked in step 4. Make a second cut on an angle toward the same point to remove a wedge and create a starting point. Now position the blade along the line and cut the circle. Sand the cut edge smooth.

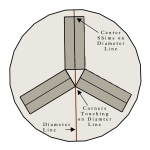

6. Position the Wood Shims

If you want the legs to stand at a greater angle, like I did, use two shims as the base for each angled top plate. Position the shims with the thickest edges closest to the center of the wood round. Adjust the placement of the three bases until their corners are touching and they are equal distance from the edge of the wood round. (Click on the drawing below to enlarge.)

7. Position the Leg Brackets

Make a mark 2 inches from the thickest edge of each pair of shims. Position an angled top plate centered on the width of each pair of shims. Adjust each plate so that its fat edge is closest to the center of the wood round and falls on the 2 inch mark you created at the beginning of this step.

8. Attach the Shims and Leg Brackets

Drill shallow pilot holes through the corners of each top plate and then secure with 3/4-inch wood screws. If the shims and plates keep shifting, it can help to make “registration marks” on each side of the shims and plates so you’ll be able to quickly tell if they’ve moved out of alignment and easily readjust.

9. Cut the Table Legs (Optional)

Using a handsaw or miter saw, cut the metal foot off each leg. Use sandpaper to round the edges of the cut.

10. Attach the Table Legs

Screw the threaded pin on each leg into a top plate.

MORE BUILDING PLANS

Monte Glover

Using the precut wooden shims to angle the legs outward I had never thought of, I have been doing woodworking for 40+ years. Thank You.

These projects look like great ones for me and the grand children. Thanks again