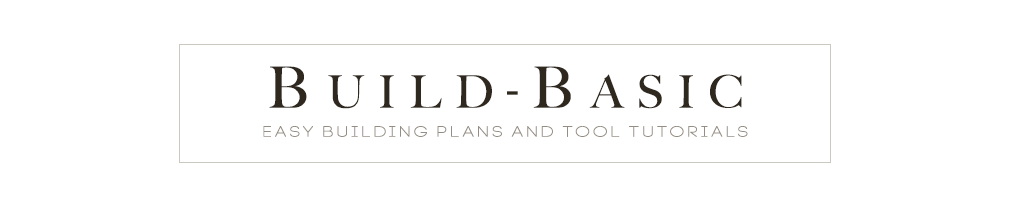

For the beer connoisseur in your life, this portable caddy is perfect for transporting handmade or locally-brewed “growlers”, or could be sized down to fit wine or regular 12 ounce bottles. The slat design is a mix of form and function, as it allows the bottles to be seen while reinforcing the strength of the tote. While at $10, the pipe handle makes this project a bit pricey, it can easily be swapped out for a wood dowel or a heavy piece of rope.

Cost: $20

Time: 3 hour

Difficulty: Easy. The simple cuts and straightforward assembly makes this a great beginner project.

(1) 1 x 6 x 4′

(3) ½ x 2 x 4′

(1) ¾ inch Pipe with threaded ends

(2) ¾ inch Pipe Floor Flange

1 ¼ inch finish nails

Wood Glue

Wood Filler

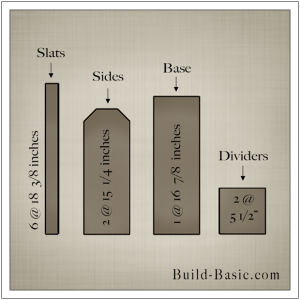

1 x 6 Base – 1 @ 16 7/8 inches

1 x 6 Sides – 2 @ 15 ¼ inches

1 x 6 Dividers – 2 @ 5 ½ inches

½ x 2 Slats – 6 @ 18 3/8 inches

Steps

1. Cut the Parts

Using a miter saw and the cut list above, cut the parts to size. Clip the top corners of the Side pieces. Sand all the cut ends to remove burrs. If you’re substituting a wood dowel for the handle, cut that now as well.

2. Mark the Base

2. Mark the Base

Using a square, mark lines on the Base piece that are 5 1/8 inches from each end. Mark additional lines 5 7/8 inches from each end. Repeat on the underside of the Base piece. The ¾ inch space between the lines is where each of the Dividers will set, evenly spaced 5 1/8 inch apart on the Base.

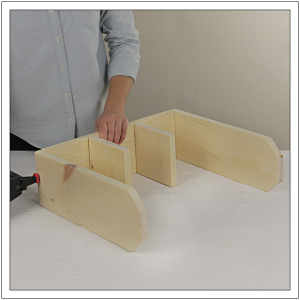

3. Attach the Dividers

Apply wood glue to the bottom edge of the Dividers and place them on the Base between the lines marked in step 2. Using the lines on the underside of the Base as a guide, shoot 1 ¼ inch finish nails through the Base and into the Dividers to hold them in place.

4. Position the Pipe Flanges

Mark the center of each Side piece near its top edge. Make an additional mark ¼ inch from the top edge of each piece. Place a flange on each Side, centered on the width of the piece, and positioned ¼ inch from its top edge. Using a drill, create shallow pilot holes in the center of each of the flanges’ mounting holes. This will allow quick and easy placement of the handle once the pieces are upright in the assembly.

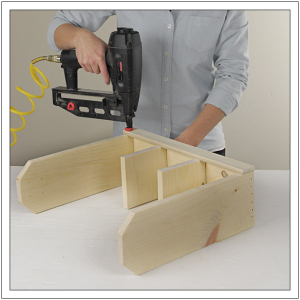

5. Attach the Sides

Apply wood glue to the ends of the Base. Place the Side pieces against the ends of the Base so that their bottom edges are flush. Nail through the Side pieces and into the ends of the Base to hold the Sides in place. I used about six 1 ¼ inch finish nails to securely hold the pieces together.

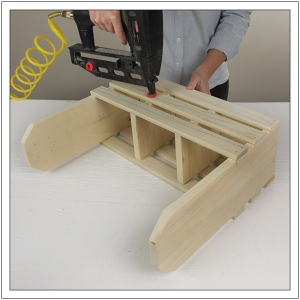

6. Secure the First Slat

Lay the assembly flat on its side. Apply wood glue along the edge of the base. Position the first Slat flush with the bottom edge of the Base. Nail through the Slat and into the edge of the Base. Send additional nails through the slat and into the Sides and Dividers. This will help reinforce the strength of the assembly.

7. Secure the Top and Middle Slats

Next, apply a dab of wood glue to the ends of the top Slat and place it on the assembly flush with the top edge of the Dividers. Nail through the Slat and into the edge of the Sides. If the Sides were tilting inward, this is the perfect chance to push them apart by making the ends of the Slat flush with the outer face of each Sides. Center the middle Slat between the top and bottom Slats, and then nail it in place.

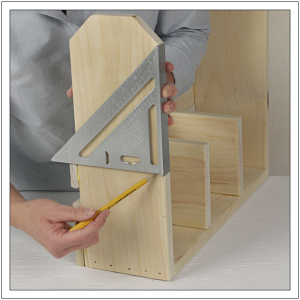

8. Transfer the Slat Positions

Using a square, transfer the height of the Slats to the opposite side.

9. Attach the Remaining Slats

On the second side of the assembly, attach all three slats in the same way as described in steps 6-7, and using the marks created in step 8. Once all the slats are installed, ensure the Dividers are perpendicular to the base (not twisted or leaning). Nail through each slat and into the Dividers.

10. Add the Handle

Once all the pieces are assembled, fill the nail holes with wood filler, let dry, and then sand the assembly smooth. Thread the pipe into the flanges, and then place it between the Sides. Align the mounting holes in the flanges with the pilot holes in each Side, and then drive ¾ inch screws through the flanges and into the Sides. Tip: If the handle spins, apply a dab of Super Glue where the threads meet the flanges to hold it in place.

MORE BUILDING PLANS

2. Mark the Base

2. Mark the Base

Anita Dwyer

I would like to have the plans to build the tree,if you could please email them to me. I love all the things you make. Thanks

Tallahassee

Thanks for the plans Jenn. It worked perfectly. No more shaken growlers on the way home. http://imgur.com/a/rJxUM

Jenn Post author

Hi There,

I just sent you an email. We’d love to feature your work! Your growler holder turned out AMAZING! Thank you for sharing! –Jenn

sherry

How Long was the pipe you used? All we had at hardware store was 12 or 18 inch. Did you have to cut pipe at all?

Jenn Post author

Hi Sherry,

I had the pipe cut and threaded to fit perfectly, but you could always lengthen the Slats and Base so that they fit the pipe sold at your hardware store. -Jenn @ Build Basic

Pingback: DIY Projects That’ll Make Drinking Even More Fun | WORLD Warotter

Mike

What type of pipe did you use for the handle? It looks darker than galvanized but it doesn’t look coated like black iron pipe. I am building a few of these and really like the look of that handle, but I can’t figure out where to get it!

Jenn Post author

Hi Mike,

Good eye! The pipe is, in fact, a black iron pipe from Home Depot. I had it cut and rethreaded right at the store, which was pretty convenient, and allowed me to make the Tote the perfect width for three Growlers. Maybe it just looks a bit lighter in the photo? I didn’t alter it in any way. Hope this helps! Let me know if you have any other questions. Also, I’d love to share your build with our readers if you want to snap a pic and send it to me at jenn@build-basic.com!

Thank you,

Jenn

JT

Jen,

What length did you get pipe cut down to at Home Depot?

JT