The word “drawer” followed by dados and dovetails is surly enough to scare off many a DIYer. Nonetheless, there’s an easier way to build a drawer without using a table saw or router, yet results in a beautiful, sturdy assembly just the same. Worried about visible fasteners? Our design cleverly hides them out of sight for a truly professional look. Follow along to see how you can quickly build any size drawer using this simple method.

Want to download this plan? Click to view Build a Basic DIY Drawer on ETSY

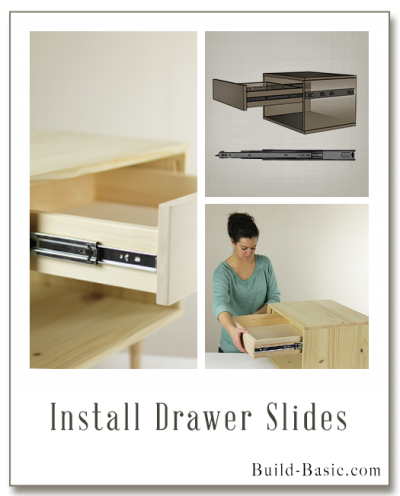

Related Tutorials: How to Install Drawer Slides & Build a Midcentury Nightstand

Cost: $6

Time: 1 ½ hours

Difficulty: Easy. Square cuts and pocket hole joinery make this a comfortable beginner project.

(1) 1 x 3 x 6 Board to make the drawer front, back and sides

(1) 1 x 6 Board to make the drawer front

(2) 3/8 x 3/8 x 3′ Square Dowel to make cleats

(1) ¼ inch Plywood to make the drawer base

(8) 1¼ inch Wood Screws to join the sides

(2) 1 inch Wood Screws to attach the drawer face

¾ inch Finish Nails to attach the cleats

Wood Glue

Wood Filler

Steps

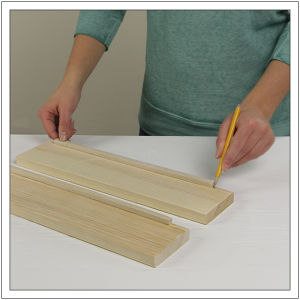

1. Cut the Parts

Using a miter saw and the cut list above, cut the 1×6, 1×3, and square dowels to size. Mark cut lines on the face of the plywood using a framing square. Place painter’s tape over the cut lines, and then mark them again if necessary. The painter’s tape will keep the plywood from splintering during the cut. Cut along the lines using a circular saw. Lightly sand the cut edges of all the parts to remove burrs.

TIP: Check out our DIY Cutting Fence Tutorial for straighter cuts without a table saw.

2. Drill the Pocket Holes

2. Drill the Pocket Holes

Place the 1×3 front and back pieces on the work surface. Using a Kreg Jig, drill two pocket holes in each end of both boards.

3. Drill the Drawer Face Holes

Place the 1×6 drawer face on the work surface with the pocket holes facing down. Using a tape measure and a pencil, make two marks 4 inches from the ends of the board, and centered on its width. Using a Drill/Driver, create two pilot holes. These pilot holes will later be used to attach the drawer face.

4. Add Cleats to the Front and Back Pieces

Position an 18-inch cleat on the 1×3 front and back pieces flush with their bottom edges and ends. Apply a bead of wood glue to the cleat, reposition it, and then nail it in place using a pneumatic nail gun and ¾-inch finish nails.

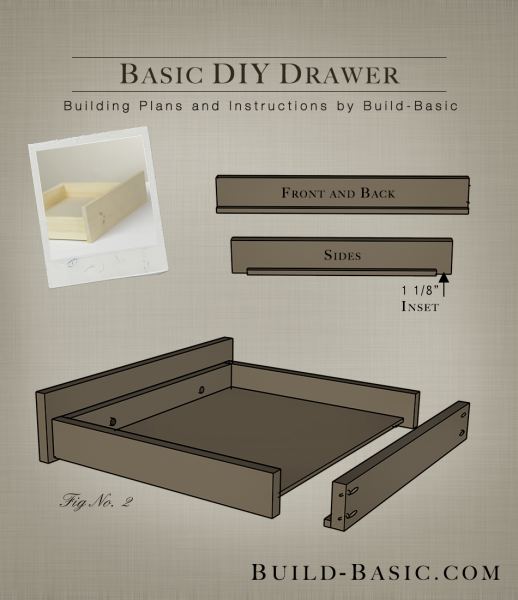

5. Attach Cleats to the 1×3 Side Pieces

Position the remaining cleats on the 16-inch-long sides flush with their bottom edges and centered on their lengths. This should create a 1 1/8-inch inset on each end of each cleat. Mark the ends of the cleats with a pencil. Remove the cleats, apply a bead of wood glue, and then put them back in place. Secure the cleats using a pneumatic nail gun and ¾-inch finish nails.

6. Dryfit the Sides

Set the 1×3 pieces upright so that the cleats run along their bottom edge. Apply glue to the ends of the front and back pieces and then position them between the sides, flush with their ends.

7. Assemble the Sides

In the name of not using fancy tools, I’ve used a very basic method for holding the joints square during assembly. Simply place a block (make sure it has a truly square corner) into the corner and clamp it tightly to each side. This will help hold the pieces in place while inserting and driving 1¼-inch pocket screws through the pocket holes and into the adjoining side. Once all four corners are assembled, check (and recheck) that the assembly is square by using a speed or framing square and measuring corner to corner.

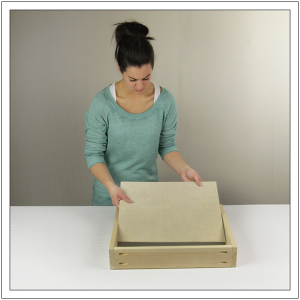

8. Insert the Plywood Base

Apply a bead of wood glue to the top edge of each cleat. Position the plywood inside the frame on the cleats.

Tip: Once the drawer is painted or stained, I like to run a small bead of clear caulk along the edges of the plywood base to keep dust from falling between the plywood and the 1x3s. Additionally, if the drawer will hold heavy objects, consider using ½ inch plywood instead.

9. Attach the Drawer Face

Center the front of the drawer on the 1×6 face. Depending on your application, allow the drawer face to hang below the drawer box. Mark the placement of the drawer on the 1×6, and then remove the drawer. Apply wood glue inside the marked area, and then reposition the drawer. Using a drill/driver, drive 1 inch wood screws through the pilot holes in the drawer front and into the backside of the 1×6 drawer face.

Tip: For a perfect fit, it’s best to fully install the drawer box, and then position and attach the face.

Tip: Check out our How to Install Drawer Slides tutorial.

MORE BUILDING PLANS

2. Drill the Pocket Holes

2. Drill the Pocket Holes

Bos'n Garcia

A Remarkable Web Site if I may say so myself. Easy to follow and easy to built instructions. When I finish, I will send you a picture of my little work shop. A converted shed from a catch all Shed to a Wood Shop. I have it wired for now with just LED lighting and power for tools. But the best is yet to come. I will install a ‘Electrical Service Panel’ to accommodate the major power tools and support outlets. The shop has carpeting for now, but upgrades are in the planning. A new window for security measures and A/C for the summer. And yes Ms. Jenn, a Microwave & Refrigerator of course for the gourmet meals & drink. You Young Lady have Inspirited me to continue building once again. I will try and remember before and after pictures. R/ Bos’n G.

Jenn Post author

Bos’n, you just made my day. You, my friend, inspire ME! I can’t wait to see photos of the new shop!

Frederick Pillivant

Place the 1×6 drawer face on the work surface with the pocket holes facing down. In step 2 in mentions the 1 x 3 front and back pieces getting pocket holes, not the 1 x 6 face in step 3. Can you clarify this?

Anonymous

My pocket hole jig is not name brand and was pretty cheap.

Pingback: 31 Woodworking Projects for Beginners | Perfect Cuts & Miters

Bob

Cost.. $6

Immediately mentions use of Kreg Jig which are $100 plus and are seldom owned by DIY’rs. I know i don’t do enough woodwork to merit the purchase of one.

Samantha Duguay

The Kreg Jig starter kit only costs $50–and that’s in CAD–for the same one used in this post! You do not need the most expensive kits, the starter kit has everything you need to do pocket holes, and you’ll also need clamps. It comes in so handy and is much cheaper than a table saw or a router, which are often used to build drawers! If you’re into DIY furniture then, in my opinion, this is an essential item that, once you have it, you’ll find a use for on just about any woodworking project, and it’s worth every penny! I didn’t think so at first, but now I have one and it’s A-MAZING! You don’t have to buy the Kreg brand, other brands sell pocket hole jigs, Kreg is just most often used.

Jd

Go to harbor freight and buy a cheaper pocket hole jig or if you can’t afford that then do a simple butt joint with screws in the end. Very simple and very cheap compared to what you’d have to do to make dovetail joints, mortises, or even doweled joints. She did a great job explaining and this is definitely a DIY easy way of making drawers.

Kudos to you.

P.S. I am a DIYer and there are also portable use-your-own clamp jogs that are much cheaper and very affordable.

Roy

I have the same Kreg Jig shown in her pictures, it’s about $24 at Lowe’s Home Improvement Store.

Paul

Not what folks consider expensive, but I sprung for the full Kreg kit, about $140 or so a few years back. They may have a higher level option now, don’t know. I’m not wealthy, but there are some things I don’t skimp on. Best to invest in quality tools, and the Kreg kit fits the bill. No regrets.

Eric Adams (@EricWAdams)

Um, I am a DIY’r and I most definitely have a Kreg jig. IT pays for itself in no time. You absolutely have to factor in your time and skill level compared to other joining techniques.

Pocket Hole are not heirloom quality, but are indispensable for quick, easy, secure joints for DIY projects. I have multiple furniture pieces around my house that I built with Pocket Holes.

You act like she was using a Festool Domino, lol.